Nylon hydrophilic silicone oil MT-8188-1

Product Introduction:

This product is a water-soluble emulsion of amino and polyether modified polysiloxane polymers. It can be used as a textile fabric feel agent and yarn smoothing agent. It has excellent feel performance, excellent hydrophilicity, minimal yellowing, and is stable.

Product features:

1. Applicable to all fiber types, the treated fabric feels soft and smooth, and has excellent hydrophilic properties

2. The fabric treated with this product has excellent lamination (lamination data attached on page 2).

3. Good stability within the range of PH=3-10, can be used in impregnation and continuous padding processes

4. No yellowing at high temperatures, especially suitable for all-white or light-colored and sensitive-colored cotton fabrics

Application process:

8188-1 is a water-soluble silicone emulsion that can be directly diluted and used. It can be used in the padding process and the washing process of ready-made clothes. The padding process is as follows:

Exhausting - Dehydration - Baking (cotton and its blends)

8188-1 20~100g/l

pH 5 ~7

Exhausting temperature 40 ~ 60

Drying and baking temperature and time 100 ~ 185 ℃ x 1-3 min

Product packaging:

1. 125 kg barrels

2. Shelf life of 180 days under airtight and cool conditions

Note: This information is based on the existing technical knowledge and experience of our company. Since there are many influencing factors in the processing and application of our products, the necessity for users to conduct their own tests is not excluded. This information also does not legally guarantee that the product is completely correct in certain properties or that it is completely suitable for particular applications.

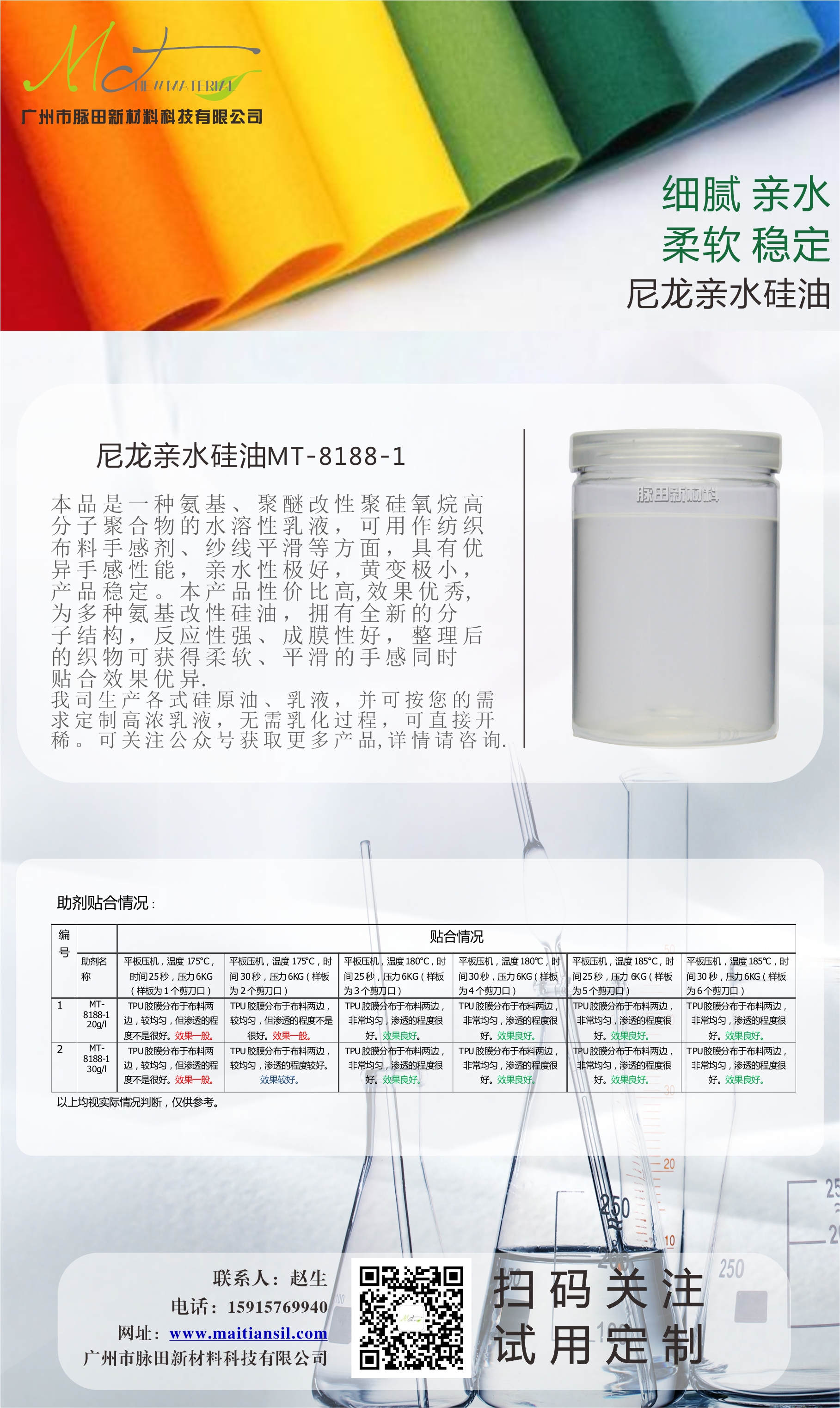

Auxiliary fit condition:

|

serial number |

|

Fitting Situation |

|||||

|

Name of auxiliary |

flat press,temperature175°C,time 25 seconds,stresses 6KG(Sample is 1 scissor opening) |

flat press,temperature175°C,time 30 seconds,stresses 6KG(Sample is 2 scissor opening) |

flat press,temperature180°C,time 25 seconds,stresses 6KG(Sample is 3 scissor opening) |

flat press,temperature180°C,time 30 seconds,stresses 6KG(Sample is 4 scissor opening) |

flat press,temperature185°C,time 25 seconds,stresses 6KG(Sample is 5 scissor opening) |

flat press,temperature185°C,time 30 seconds,stresses 6KG(Sample is 6 scissor opening) |

|

|

1 |

MT-8188-1 20g/l |

The TPU adhesive film is distributed on both sides of the fabric and is more uniform, but the penetration is not very good. The effect is general. |

The TPU adhesive film is distributed on both sides of the fabric and is more uniform, but the penetration is not very good. The effect is general. |

The TPU adhesive film is distributed on both sides of the fabric, very evenly and penetrates well. The effect is good. |

The TPU adhesive film is distributed on both sides of the fabric, very evenly and penetrates well. The effect is good. |

The TPU adhesive film is distributed on both sides of the fabric, very evenly and penetrates well. The effect is good. |

The TPU adhesive film is distributed on both sides of the fabric, very evenly and penetrates well. The effect is good. |

|

2 |

MT-8188-1 30g/l |

The TPU adhesive film is distributed on both sides of the fabric and is more uniform, but the penetration is not very good. The effect is general. |

TPU adhesive film is distributed on both sides of the fabric, which is more uniform and penetrates to a better extent. The effect is better. |

The TPU adhesive film is distributed on both sides of the fabric, very evenly and penetrates well. The effect is good. |

The TPU adhesive film is distributed on both sides of the fabric, very evenly and penetrates well. The effect is good. |

The TPU adhesive film is distributed on both sides of the fabric, very evenly and penetrates well. The effect is good. |

The TPU adhesive film is distributed on both sides of the fabric, very evenly and penetrates well. The effect is good. |

The above are determined based on actual conditions and are for reference only.